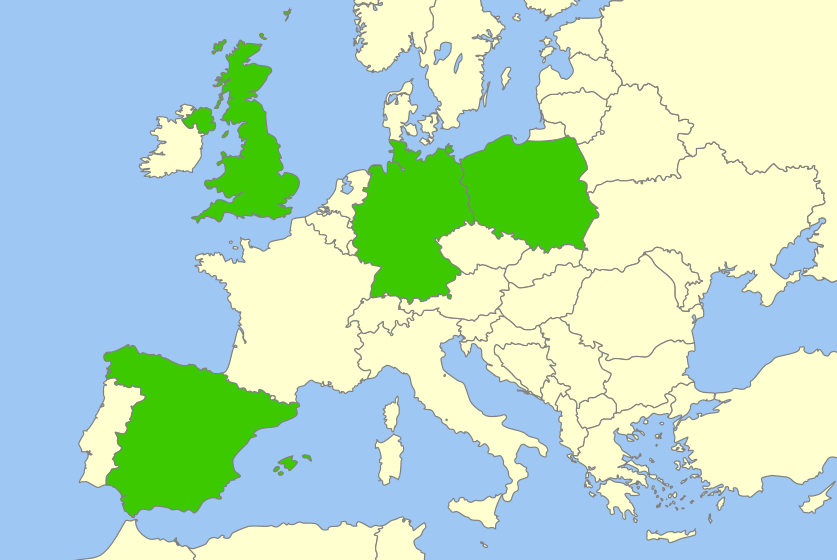

PRASS III project is realized by a consortium of seven partners from four different countries with important coal mining industries, which enable including the variety of mining conditions across Europe. The consortium includes a participation of industry, research institutions and universities, thus allowing both laboratory and mine tests.

Instytut Techniki Górniczej KOMAG is state owned research and development centre of organizational and proprietary structure adapted to the market activity in the European Research Area and of the organizational culture creating a friendly climate for generating new ideas and realizing the innovative activities, i.e. transforming new ideas into new products. The KOMAG activity incorporates scientific and research projects on improvement of mining technology, haulage and processing of minerals. The projects are oriented onto anthropotechnical systems in the aspect of reliability, work safety and comfort. The Division of Mechatronic Systems employs an interdisciplinary team of specialists, who can realize complicated mechatronic projects, which combine mechanics, automation, computer science and electronics, taking advantage of the synergy effect.

The range of scientific, research and technical projects, realized by the Division of Mechatronic Systems, is as follows:

- designing and integration of automation systems, monitoring and industrial sensor technologies based on different hardware platforms,

- designing and construction of mechatronic systems,

- designing of pneumatic systems,

- modelling and simulation of mechatronic systems,

- designing of systems for visualization of technological processes in various environments,

- a development of customer and server applications,

- a creation of applications, websites and internet services,

- designing and implementation of microprocessor electronic systems,

- vibrodiagnostics of machines and equipment,

- analyses of images from vision and thermovision cameras.

An integration with the European Research Area as regards designing, testing and manufacture of machines as well as an increase in competiveness of Polish solutions in the European market is the main objective of the activities undertaken by KOMAG within the basic and strategic tasks. A close collaboration with foreign partners, representing the leading institutes in Europe, plays an essential role. During last 10 years KOMAG was participating in 15 European projects within such programmes as: V. and VI. Framework Programme, Research Fund of Coal and Steel, COST 356, Leonardo, ERASMUS +. At the moment KOMAG is coordinating two international projects of a total budget 3 622 842 euro.

Główny Instytut Górnictwa (GIG), created in 1945, is a Polish governmental research institute engaged in problems of mining engineering, safety in mines and environmental protection in the hard coal mining sector. The multidisciplinary activities of the Institute comprise the following fields: • mining engineering, geology and hydrogeology, geophysical engineering • combating natural and technical hazards in the mining industry, • upgrading and utilization of minerals and reserves • monitoring and environmental protection in areas of mining exploitation, especially industrial waste management, certification of equipment and materials. GIG employs a staff of 586, including over 448 graduates, more than 112 of whom hold PhD or DSc degrees. A part of the Institute constitutes the Experimental Mine “Barbara” established in 1925. GIG has extensive experience of acting as partner and co-ordinator of EU Programmes and RFCS projects. Currently GIG is involved in 23 EU co-founded research and development projects ie.: RFCS Projects (5 coordinated by GIG, 12 in total), 7 FP – 3 on-going projects, 2 ongoing projects in HORIZON 2020 and others. Department of Extraction Technologies And Mining Support will lead work in the Project. The research area of the Department relates to rockburst hazard, geomechanics (e.g. stability, rockmass parameters, load, convergence), support (longwall, roadways support and shaft lining) and extraction systems. The range of numericall modelling codes (UDEC, Phase, Flac, PFC, RS3, Cosmos, Ansys, Solid Works), own developed empirical methods and unique equipment (penetrometer, borehole camera, shaft inspection probe, rock cutability assessment device, ground penetration radar) are used for research work (EU and Polish bodies founded projects) and for commercial services for Polish and overseas customers (more than 200 projects/year of support quality assessment, support design, rockmass conditions determination, coal extraction planning and assessment). The Department successfully completed 8 RFCS projects (PR 115, MONSUPPORT, PROSAFECOAL, MINTOS, IMPREX, MISSTER, GEOSOFT, LOWCARB), currently is involved in 3 (STAMS and as o co-ordinator: AMSSTED, COGAR) and in 1 under 7 FP (I²Mine).

DMT GmbH & Co. KG (DMT), headquartered in Essen, Germany, is an independent engineering and consulting company, active at international scale. DMT employees, most of them engineers, scientists and technicians, provide services in the form of individualised consulting and assistance. They also serve as impartial assessors. The firm’s activities focus on the fields of natural resources exploration, mining and cokemaking technology, construction and infrastructure projects, safety in buildings, product testing and measurement instrumentation in industrial settings. Using methods and techniques drawn from the fields of geology and hydrogeology, geophysics, geodetics and geotechnology, DMT supplies the data needed to achieve planning reliability for the extraction of natural resources (minerals, oil and gas, coal, salt, deep geothermal energy and others), for relieving the environment (carbon capture and sequestration, reducing CO2 emissions etc.) and for special-purpose civil engineering (tunnelling, hydro power plants, energy storage systems). Our work, concentrated in a single company and reaching all around the world, begins with planning, includes surveying and interpretation and extends to modelling and the final evaluation. And to ensure the very best results we also develop, operate and market our own geo-surveying and monitoring systems. DMT and its subsidiaries have undertaken competent research (Amongst others: EU, The World Bank, RFCS),dissemination and exploitation, feasibility study, due diligence, financial analyses, support to investors, institutional strengthening, mineral exploration, mining engineering, geological and environmental remediation projects as well as seismic monitoring and hydrometallurgical simulation at all levels. Since 2007, DMT is a member of the TÜV NORD Group (TNG) in Germany. With over 10,000 employees in more than 70 countries of Europe, Asia, America and Africa. DMT owns a research and development section for the development and manufacturing of engineering technology for various industries. In our laboratories and workshops we build prototypes, make instrumentations and modify available systems for special purposes with a main focus on data acquisitions and interpretation systems. Aside development of customized instrumentation solutions, DMT is an internationally recognised manufacturer of geophysical and geodetic instruments for more than 25 years. DMT is registered as expert body in the fields of mining induced surface movements, impact to infrastructures and buildings as well as on induced seismological impacts. This includes labs with monitoring equipment, modelling and prediction software as well as experts with specific knowledge, expertise and reputation. For geological investigation DMT uses the following infrastructures: core scanner, geophysical borehole tools and several relevant software products. Also DMT will use the available testing rigs for support elements and the testing center for concrete, as well as modelling software Flac 2D and 3D.

Becker Warkop Ltd. Company (BW), with its headquarters located in Swierklany, was formed in 1991 as a joint venture company based on agreement between polish partner Warkop Sp. z o. o. and Walter Becker G.m.b.H (Germany) – currently Becker Mining Systems A.G. The basic idea of the creation of Becker Warkop was cooperation in sales, manufacturing and service transport systems for mining, based on floor mounted rope driven haulage system. After a dozen years of activity, Becker Warkop Company has specialized also in powered roof supports manufacturing. Currently, we are one of the valued powered roof supports manufacturer. The powered roof supports delivered by Becker Warkop Company are used in many mines and are operating in seams with thickness from 1.2 m to 4.5 m. The powered roof supports are designed and manufactured according to the newest technological solutions. Additional activity is design and distribution of electric, electronic and computer solutions for mines developed in the Becker group of companies and its own design office. Many solutions like power-on systems, control systems, communication and visualization systems to support production processes in the mines were implemented for both Polish and overseas markets. The surface area of the workshops is 6 400 m2. Complete area of the Company is 4,5 hectare. Number of employees is 320 people.

UNEXE – University of Exeter. The University of Exeter (UNEXE) is a member of the Russell Group, which is committed to maintaining the very best research, an outstanding teaching and learning experience and unrivalled links with business and the public sector. Exeter was voted the Sunday Times University of the Year 2012/13. It is ranked amongst the UK’s top 10 universities in the Higher Education league tables produced by the Times, the Guardian and the Sunday Times. It is also ranked amongst the world’s top 200 universities in the QS and Times Higher Education rankings. The University of Exeter has significant experience of participating in and managing international research projects, and has participated in more than 170 EU funded research projects. The UNEXE research team are based at the Camborne School of Mines (CSM), and is a multidisciplinary research institute that brings together expertise from the worlds of civil and mining engineering, geology and minerals engineering. UNEXE carries out both fundamental and applied research, funded from European and National sources in a range of mining, geology, minerals and geotechnical areas. Research areas include numerical analysis, rock mineralogy, rock mechanics and rock breakage, mining and minerals technology.

Geocontrol is a leading independent civil engineering consultancy specialized in underground works, which was established in 1982. Located in Madrid (Spain) the company has extensive experience in mining and in the modelling, design and testing of tunnels, including tunnel safety equipment and infrastructure. The works performed throughout these years have allowed to Geocontrol, S.A. to participate in projects and technical support of more than 342 of all kind of tunnels which adds up to more than 1.000 Km, as well as in supervision and reparation of 756 tunnels, with a total length of 500 km. Since 1991, Geocontrol has carried out more than 25 R&D projects belonging to different EU programmes: 9 ECSC,12 RFCS (PRESIDENCE as Coordinator, GEOSOFT, MISSTER, COMEX, INREQ…), 2 EUREKA SECRETARIAT, 2 EURATOM, and 1 BRITTE. The company has actually a technical staff of more than 75 employees which is distributed between the offices of Spain and Latin America (Chile, Brazil, Peru, Colombia).